Fillet Rolling

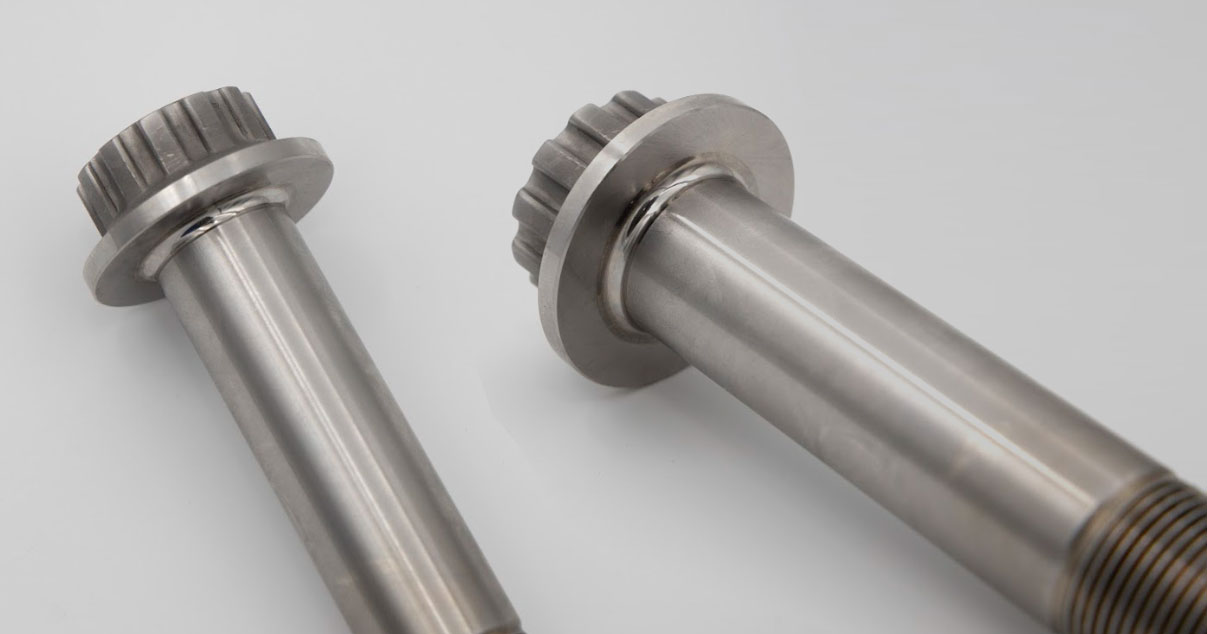

Superior Thread Rolling offers fillet rolling as a stand-alone service when needed. More commonly, we offer this as a complementary service alongside a project requiring thread rolling and/or centerless grinding.

Fillet Rolling, Grinding, and Thread Rolling

Do you have a project requiring fillet rolling? Superior is your one stop shop for these projects! Many fatigue-rated bolts and other fasteners require fillet rolling in addition to thread rolling. At Superior Thread Rolling, we can offer to finish grind, fillet roll, and thread roll all in the same order. That allows us to perform all the required testing and control all the key operations so you can rest assured your parts will pass fatigue testing and perform as your customer desires.

What is Fillet Rolling?

Fillet rolling is performed by machinery which applies pressure at 45 degrees to the 90 degree underhead fillet radius of a component part. Using 3 dies on a spinning part, this process uses cold working techniques to reform the material surface, creating a compressive effect.

Why is Fillet Rolling used?

Fillet rolling is a technique that greatly increases the fatigue strength of components. This strengthening process works by hardening the radius under the head of the screw, where stress corrosion cracks are most prone. As a result, STR is able to use this process to slow down or even entirely prevent cracking dispersion.

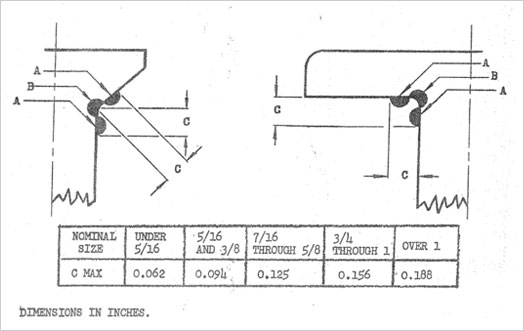

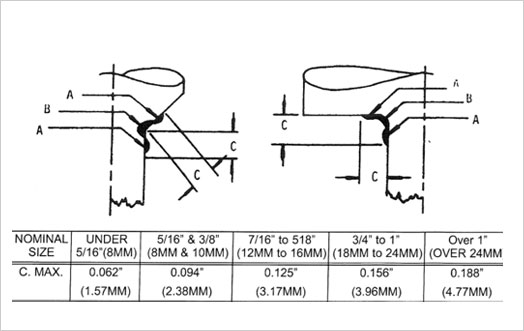

Choosing the right Fillet Roll dies

Superior Thread Rolling holds an assortment of die blanks on hand, allowing us to quickly create new custom dies for our customers’ custom fillet rolled parts. There are a few key factors to consider when planning these specialized projects however, which we map out in diagrams below:

Permissible Distortion

Die Diameter VS. Headswing

Inspection of Fillet Rolling

As with every Superior Thread Rolling service, our company prioritizes quality by performing thorough inspections. Concerning fillet rolling projects, our team uses a couple integral inspection tools:

Precision Comparator

Precision comparators are used to check the accuracy of fillet roll operations, ensuring that each die setup is properly calibrated. Furthermore, this equipment is essential to the fillet rolling inspection process because it allows our team to verify predicted fatigue life improvements.

Vision Inspection System (OASIS)

The vision inspection system, or OASIS, is highly advantageous when inspecting and monitoring fillet rolling projects. This system is impressively precise, boasting accuracy to +/- 0.0001 inches and 2D measurement machine vision. Not only that, but OASIS allows for data retention, making customer use easier for future projects! With a ready to run complete Turn-Key Package, this user friendly technology allows Superior Thread Rolling to exceed QA Inspector standards for every order.