Thread inspection is an important part of the manufacturing process to ensure the parts conform to customer specifications. If the parts aren’t checked for cracks, the threads could break, causing premature failure. If their dimensions aren’t accurate, then the parts won’t fit properly which could stop an entire assembly line and cause revenue loss.

There are two major parts to quality thread inspection. The first is to ensure that the threads are dimensionally accurate, according to the design’s requirements and the function that the part will serve. The other major part is a metallographic inspection for seams, cracks, and proper grain flow. All of this serves to ensure that the part functions exactly how it’s meant to.

Thread Inspection – Dimensional Inspection

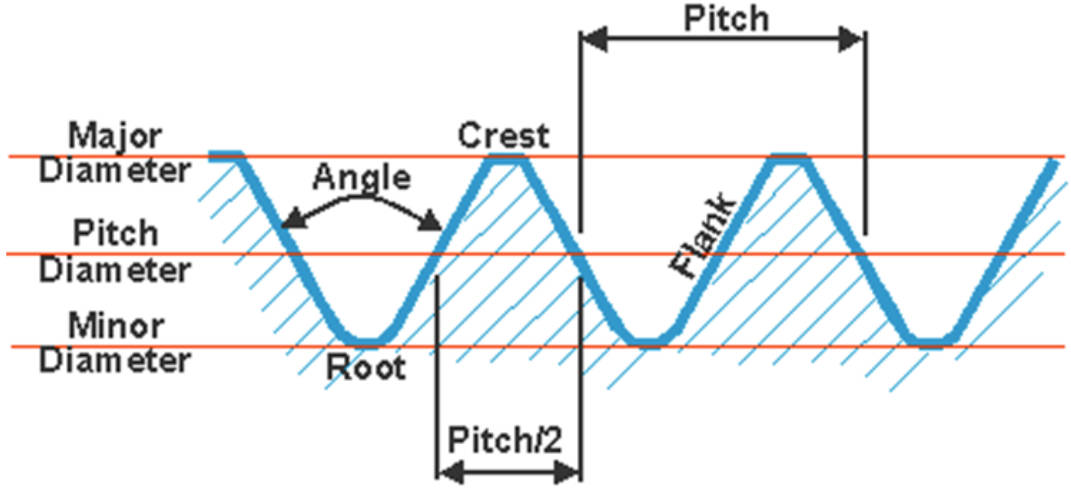

Dimensional inspection is an important thread inspection process for the functionality of the fastener. It ensures that the thread fits into its mated piece (within the part it was designed for) and that its fit matches the function it was designed for. Inspection of the individual threads on the component ensures that they are within tolerances and pinpoints any specific inaccuracies. This includes ensuring that the pitch diameter, and the major and minor diameters of the threads are all accurate to the design

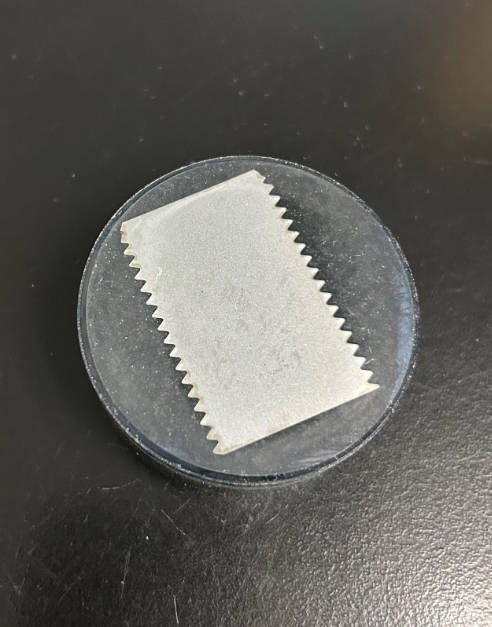

Ring gauges, like this one, ensure that the component’s dimensions line up with its function–that the part will fit into its mated piece. Dimensional inspections also ensure the threads meet the requirements of their fitment classes, which determine the part’s final function.

There’s more than just size and shape to consider with tread inspection. Many parts will undergo some sort of coating or plating process, which changes the dimensions. Allowances for this should be planned ahead of time in the design.

Thread Inspection – Metallographic Inspection

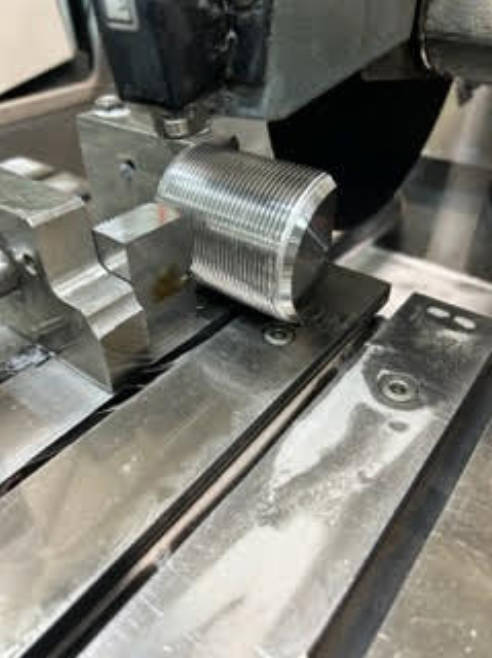

We discussed grain flow a little in our previous post on the importance of thread rolling. Thread rolling doesn’t interrupt the grain flow, but compresses it. If the grain flow is interrupted, as seen in the diagram below, then that is a sign that something is wrong. Metallographic inspection is the thread inspection process that ensures that the grain structure of the material is not interrupted or otherwise damaged.

Metallographic inspection is a destructive test. It involves physically cutting the thread off of the part, and then cutting that piece in half in order to examine a cross-section of the thread’s interior.

This allows the inspector to make sure that the seams on the parts are within acceptable limits and that the grain flow of the metal is uninterrupted. Non-destructive testing–penetrant and mag particle inspection–can’t distinguish between what structures are acceptable and what aren’t.

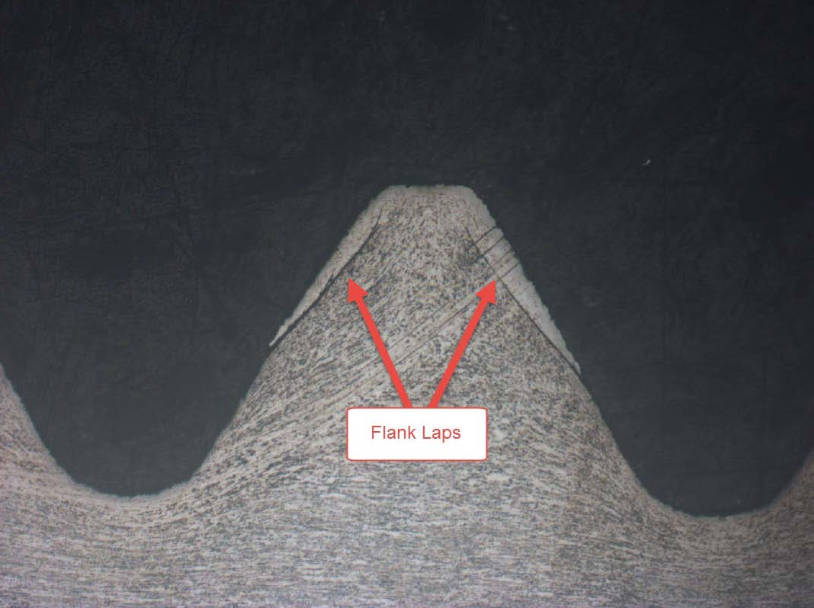

Seams are folds in the material that occur during the rolling process. Some seams are detrimental to the thread’s performance, while others have no effect. Seams located at the crest of the thread are found on all rolled threads and deemed acceptable so long as they aren’t too deep. Seams on the root or flank of the thread, depending on their size and orientation, can negatively affect thread performance. The images below are an example of unacceptable seams on the root (left image) and the flank (right image) of the thread that were caught during the thread inspection process.

Metallographic inspection is a vital part of ensuring that your threads are up to standard and ready for operation.

How testing requirements relate to a component’s function

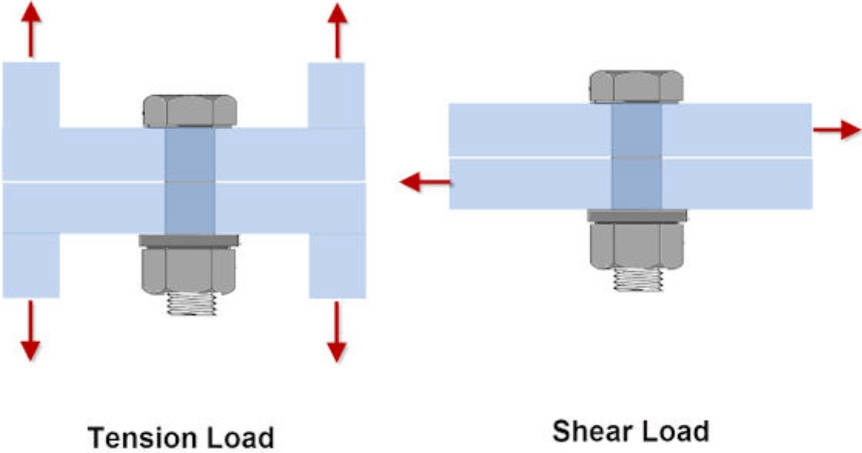

The requirements that a component must meet are in part a direct result of the component’s function. Fasteners, the most common thread-rolled pieces, are used in a lot of different ways and some fasteners have different requirements than others as a result. Some are tightened into place and held in constant tension, and require tensile strength, while others require sheer strength and have to undergo strength from the opposite direction as shown below:

Still other fasteners have to undergo repeated tension and relaxation and thus require high fatigue strength. Testing, using equipment like that shown in the image below, allows the manufacturer to simulate how the part could fail and make sure that it meets performance requirements. This is just one of the many reasons thread inspection is so important.

Looking for a supplier of thread forming and CNC manufacturing that adheres to strict thread inspection processes?

The Superior Thread Rolling Company has been a supplier of choice for critical components in Aerospace, Defense, and many other applications. Our adherence to strict thread inspection processes helps ensure precision and quality in critical components. To learn more, contact us today!