Examining the use of Liquid Penetrant and Magnetic Particle Inspections in Non-Destructive Testing

Non-destructive testing (NDT) is a common testing method in finding cracks and defects during quality inspection of threaded components. Liquid penetrant testing and magnetic particle inspection are the most commonly used industry-standard NDT processes. While both methods are very useful, they are each better suited to different types of threads and materials. Understanding the types of threads you are working with will help you better understand the results of these two major types of non-destructive testing.

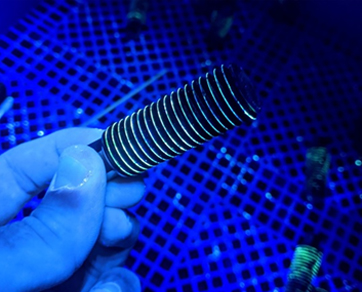

Non-destructive testing for threads

Surface vs. Subsurface defects

Surface defects are any cracks that are open to the surface or major porosity. These are the only defects that can be detected through Liquid Penetrant inspection.

Subsurface defects are cracks or faults found within the material that are not open to the surface. Magnetic Particle inspections are best for finding subsurface defects.

Liquid Penetrant Inspection in Non-Destructive Testing

Penetrant examinations are a popular NDT method, being economical and versatile. This type of inspection relies on having a seam or crack open on or to the surface. A thin liquid flows over the component, usually a thin layer of an oil and water mixture combined with fluorescent particles. If there is a crack on the thread’s surface, the particles will flow into it and start to glow.

Liquid penetration is advantageous because it’s a simple, low-cost method that can be applied to any non-porous and clean material whether magnetic or nonmagnetic, as long as the surface is smooth and free of debris.

Magnetic Particle Inspection in Non-Destructive Testing

Magnetic particle inspection is excellent for detecting surface and near-surface flaws in ferromagnetic materials. Primarily, this method is used for detecting cracks in the threads. Mag particle inspection works very similarly to liquid penetrant, however iron particles are added to the oil and water mixture in order to help create a magnetic field across the part. Fluorescent particles can then flow across the field, and react when they find interruptions, revealing the defects in the surface.

Mag particles are excellent and highly accurate, but they only work on metals that can be magnetized, like ferritic steels and irons. Because this method detects surface and subsurface defects, it will find more indications than penetrant inspections.

Cut Threads vs. Rolled Threads

While NDT is useful for inspecting threads, many NDT methods can falsely reject rolled threads. Unlike cut threads, rolled threads have a natural seam that doesn’t have any effect on the part’s performance. Magnetic particle and liquid penetration inspections will enter the crevice and indicate that the seam is there. It’s important for inspectors to understand the differences between cut and rolled threads and recognize this seam–otherwise they may reject a part that’s actually perfectly fine.

Looking for a supplier of quality rolled threads?

Superior Thread Rolling has decades of experience in rolling threads that meet many different quality standards, including NDT standards for liquid and fluorescent penetrant inspection and magnetic particle inspection set by Boeing, Bell, Bombardier, and NADCAP. Check out our website to learn more!