DMAIC and Lean Manufacturing

DMAIC is a structured approach to lean manufacturing – finding and fixing issues within a production line, system, or work center, with the aim of continually improving the process. A designated project team analyzes any issues in the process, and then prioritizes them based on their impact on the efficiency of the operation. Once a solution has been found and tested, the project team not only circles back to ensure that the problem is under control, but then starts on the next issue on the list.

Define

This is the process of determining the actual problem and assigning team members, budget, time and other resources to finding a solution for the problem.

Measure

The team assigned to finding a solution then has to get metrics for the problem, whether that’s examining measurements already in place, or establishing them anew. This allows them to gain a better understanding of the problem, establish a baseline, and then continuously measure it during the cycle, and afterwards to test the solution they implement. This can involve both simple measurements as well as complex and in-depth statistical analyses.

Analyze

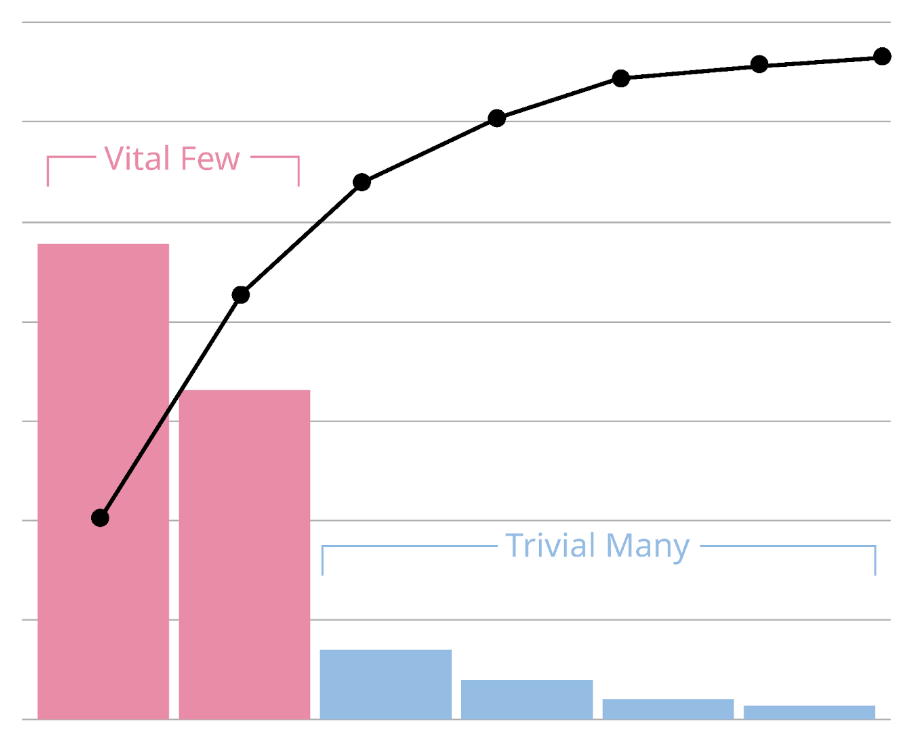

In this part of the cycle, the team analyzes the metrics they compiled to determine why the problem is happening. A good approach is to include shop floor employees who are actually involved in the process being analyzed, relying on their valuable insight and experience to help find the cause of the problem. Another way that this data is often analyzed is through a Pareto Chart, which examines the number of incidents happening and how often each one occurs. This way, the team can determine the most common incident, which allows them to better focus on the root cause of the problem.

Improvement

Once the metrics have been identified and analyzed, the team determines what they think is the root cause of the problem and implements a solution. This could be any number of things, from new training for employees, better computer software, a redesigned workspace, cleaning, and more. Then, the team compares the metrics after the solution has been implemented to the original baseline to see if there has been a beneficial effect on the process.

Control

Just implementing a solution isn’t enough–after that’s done, the team assigned to the problem continues to monitor the process to ensure that the improvement is actually working. They continue to take measurements and document the process for days, weeks, or even months, and then compare the results to the initial metrics. If the metrics don’t improve then the team circles back the Improvement phase to try again. The DMAIC can be used repeatedly on the same process to continuously drive improvements.

The 5 S’s of Lean Manufacturing

These five terms are vital to lean manufacturing and refer to the organization of tools on the shop floor, and provide a method for maintaining a clean and uncluttered work area for employees that reduces wasted time and movement. This in turn leads to improved lead times and product quality for customers.

Sort

When launching 5S in the work center, make sure there is nothing unnecessary there, such as unrelated tools or other items. Any items or tools not used weekly should be removed.

Set and Order

After everything is sorted, the remaining items are given a spot or label to ensure that the workspace remains ordered and organized.

Shine

This refers to keeping the workspace clean, performing daily tasks and ensuring that everything is back to its spot at the end of the day.

Standardized

The management of the shop floor should set the standard for how much time is spent cleaning, when it should be considered finished, and what tooling is common for the workspace–which includes procuring tools from the same manufacturer(s) and keeping spares nearby if something were to break.

Sustain

This refers to ensuring that cleanliness and organization of the workspace are maintained. This often comes in the forms of audits by management or the supervisors, in order to keep everyone accountable for maintaining their workspace each day.

Safety

While commonly there are only five ‘S’s’, American companies, and Superior Thread Rolling among them, add on Safety as another foundation. This includes being in compliance with workplace safety regulations, such as those set by OSHA.

Gemba Walk in Lean Manufacturing

A Gemba Walk is a lean manufacturing process in the workplace where a walkthrough is done by supervisors or management to observe employees, ask about their tasks, identify productivity gains, and maintain communication with the shop floor. It also allows management to get insight from employees on potential improvements that could be made to their workcenter’s efficiency and organization.

How Lean Manufacturing Benefits Customers

Manufacturers that implement these and other major practices in lean manufacturing have more opportunities to offer benefits to their customers, such as:

- Reduced lead times

- Improved product quality

- Reduced costs

- Elimination of waste, including time, movement, and materials

- Improved on-time delivery

By continually improving processes and workflow, lean manufacturing offers more efficient and productive services to customers, reducing their costs and providing them with higher quality products.

Looking for a supplier of thread rolling and CNC machining services?

Superior Thread Rolling is a leading aerospace manufacturer with over seventy years of experience. We have implemented many principles of Lean manufacturing, including those listed above with great success. Our adherence to these lean manufacturing principles has contributed to our operation’s success over the past seventy years. Contact us to learn more about what we can do for you.